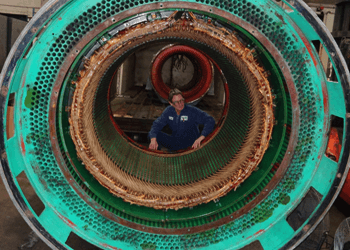

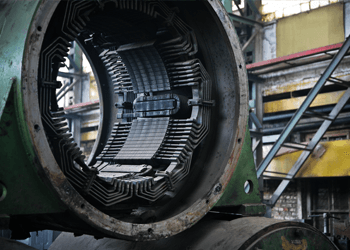

RAM is an expert in motor shop services as well as pump and transit applications. Our technicians have the experience and technology to analyze, diagnose, and repair rotating electoral and mechanical apparatus.

RAM works 24/7 to minimize downtime and maximize performance. We are experts on motor shop services.